Commercial Pressure Washing and Exterior Cleaning in Dallas

Restore curb appeal and protect your property investment with professional exterior cleaning services

Commercial Pressure Washing and Exterior Cleaning in Dallas

Restore curb appeal and protect your property investment with professional exterior cleaning services

First impressions matter in business, and your property's exterior is the first thing customers, clients, and employees see. Over time, commercial building exteriors accumulate dirt, pollution, mold, mildew, and stains that diminish appearance and can damage surfaces if left untreated. For Dallas businesses, where intense sun, dust, and occasional severe weather accelerate exterior deterioration, professional pressure washing and exterior cleaning services are essential maintenance investments.

Professional exterior cleaning goes far beyond rental equipment and DIY attempts. Trained technicians understand the appropriate pressure, temperature, cleaning solutions, and techniques for each surface type—from delicate building facades to durable concrete loading docks. Proper cleaning removes contaminants that etch and degrade surfaces while preparing substrates for protective treatments. For Dallas commercial properties, regular professional exterior cleaning preserves property value, enhances curb appeal, creates welcoming environments for customers and employees, and demonstrates the attention to detail that reflects well on your business.

Pressure Washing vs. Soft Washing Techniques

Professional exterior cleaning employs two primary approaches: pressure washing using high-pressure water, and soft washing using low-pressure application of cleaning solutions. Understanding when to use each method is essential for effective cleaning without surface damage.

Pressure washing uses concentrated water pressure (typically 1,500-4,000 PSI) to blast away dirt, stains, and contaminants. This method works well for hard, durable surfaces including concrete, brick, stone, and some metal surfaces. Pressure washing quickly removes loose paint, heavy soil accumulation, and deeply embedded stains. However, excessive pressure damages softer materials, forces water into building envelopes, and can etch surfaces.

Soft washing applies cleaning solutions at low pressure (similar to garden hose pressure), allowing chemicals to do the work rather than mechanical force. This method is appropriate for: building siding including vinyl, wood, and fiber cement; roofs and shingles; painted surfaces; windows and glass; and delicate masonry. Cleaning agents target specific contaminants—algaecides for algae, surfactants for dirt, mildewcides for organic growth.

Professional services assess surface types and contamination to select appropriate methods. Many projects combine both approaches—soft washing building facades while pressure washing concrete surfaces. For Dallas properties, technique selection considers local conditions including intense UV exposure that degrades some materials and makes gentle cleaning essential.

- -Appropriate method selection by surface type

- -Pressure washing for durable surfaces

- -Soft washing for delicate materials

- -Chemical-specific cleaning agents

- -Combined approaches for comprehensive cleaning

Building Facade and Siding Cleaning Methods

Building facades require careful cleaning appropriate to the specific materials and construction. Professional services understand the techniques that clean effectively without damaging expensive building exteriors.

Brick and masonry cleaning addresses atmospheric soiling, biological growth, and efflorescence (white salt deposits). Appropriate pressure and cleaning solutions remove contaminants without damaging mortar joints or brick faces. Historic brick may require gentle soft washing to preserve aged surfaces. Post-cleaning sealers protect against future staining.

Vinyl siding cleaning removes oxidation, algae, and environmental soiling that dulls appearance. Soft washing with appropriate surfactants restores color without the damage that high-pressure spraying can cause to siding seams and attachments. Care around windows, vents, and utilities prevents water infiltration.

Stucco and EIFS (Exterior Insulation and Finish Systems) require low-pressure cleaning to prevent damage to the finish coat. Specialized cleaning solutions address biological growth common in humid conditions without degrading the synthetic finish. Wood siding needs gentle cleaning that removes dirt while preserving finishes and preventing water absorption that leads to rot.

For Dallas commercial buildings, facade cleaning enhances street presence while protecting the exterior envelope from degradation that leads to costly repairs.

- -Material-specific cleaning protocols

- -Gentle techniques for delicate surfaces

- -Appropriate pressure and chemical selection

- -Water infiltration prevention

- -Post-cleaning protection options

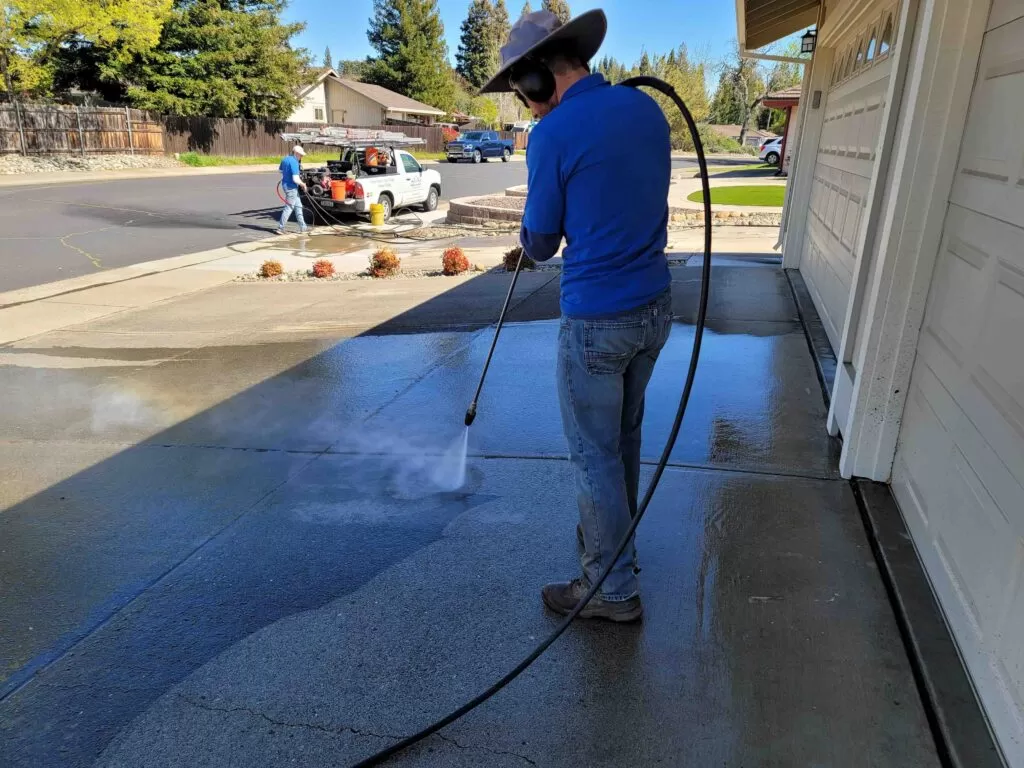

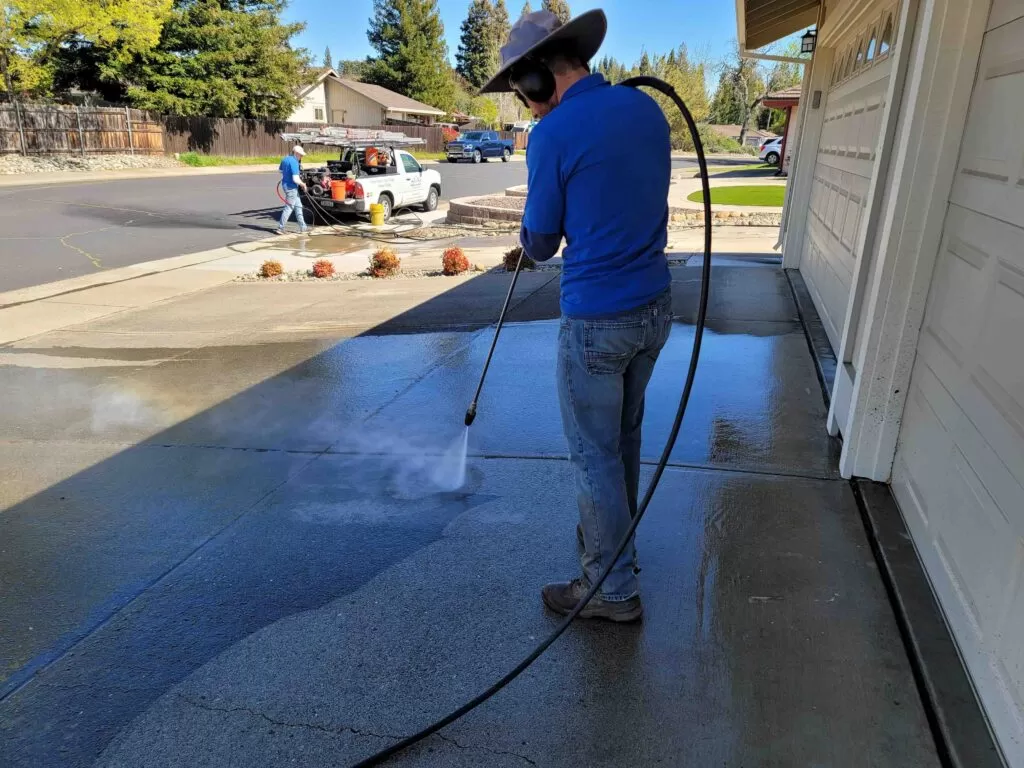

Concrete Surface Restoration and Stain Removal

Concrete surfaces including parking lots, sidewalks, loading docks, and building aprons accumulate some of the toughest stains and heaviest soiling. Professional concrete cleaning restores appearance and removes contaminants that create slip hazards and accelerate deterioration.

Pressure washing removes surface dirt, tire marks, and general soiling from concrete. Surface cleaners—rotary pressure washing attachments—provide uniform cleaning across large areas without streaking or striping. Different pressure levels address various concrete ages and conditions—new concrete requires gentler treatment than aged, cured surfaces.

Oil and grease stain removal requires specialized degreasers that break down petroleum products for pressure washing removal. Heavy automotive fluid stains may need multiple treatments or poultice applications for complete removal. Rust stains from irrigation systems or metal fixtures respond to specific rust removers that don't damage concrete.

Gum removal uses high-pressure hot water or specialized solvents to dissolve and remove accumulated chewing gum. Efflorescence (white mineral deposits) removal addresses the salt deposits that indicate moisture issues and create unsightly surfaces. Sealant application following cleaning protects concrete from future staining and extends cleaning results.

For Dallas commercial properties, clean concrete enhances safety, improves appearance, and demonstrates property management attention to detail.

- -High-pressure surface cleaning

- -Oil and grease stain removal

- -Gum and organic matter elimination

- -Efflorescence treatment

- -Protective sealing applications

Parking Garage and Loading Dock Cleaning

Parking garages and loading docks present unique cleaning challenges due to heavy vehicle traffic, petroleum product exposure, and often limited drainage. Professional cleaning addresses these demanding environments comprehensively.

Parking garage cleaning removes automotive fluids, tire marks, dirt tracked in by vehicles, and exhaust residue that coats surfaces. Multi-level garages require water containment and collection to prevent discharge into storm systems. High-pressure washing with appropriate degreasers removes petroleum stains while managing water runoff. Wall and column cleaning addresses splash marks and accumulated soil.

Loading dock cleaning tackles heavy soil from delivery vehicles, forklift traffic, and material handling. Oil and hydraulic fluid stains require aggressive treatment. Debris removal addresses packing materials, pallet fragments, and accumulated trash. Floor cleaning removes rubber marks, soil, and spills that create slip hazards.

Drain maintenance ensures proper water removal during and after cleaning. Some facilities require dry cleaning methods or water recovery systems to meet environmental discharge requirements. Coordinated scheduling with facility operations minimizes disruption to receiving and shipping activities.

For Dallas commercial facilities, clean parking and loading areas create positive impressions, improve safety, and support regulatory compliance.

- -Automotive fluid and tire mark removal

- -Water containment and recovery

- -Wall and vertical surface cleaning

- -Drain maintenance and cleaning

- -Operational scheduling coordination

Graffiti Removal and Surface Protection

Graffiti vandalism creates immediate negative impressions and, if left untreated, encourages additional vandalism. Professional graffiti removal restores surfaces while protective treatments make future removal easier.

Graffiti removal techniques depend on the surface type and graffiti medium. Porous surfaces like brick and concrete absorb paint, requiring poultice applications or specialized strippers that draw paint out without damaging substrates. Non-porous surfaces like glass and metal allow solvent-based removal. Historic or delicate surfaces need gentle techniques preserving original materials.

Removal timing affects results—fresh graffiti removes more easily than aged, weathered paint. Shadowing (residual staining after paint removal) may remain on porous surfaces, requiring additional treatment or repainting. Multiple removal methods may be tested to identify the most effective approach for specific situations.

Anti-graffiti coatings provide sacrificial or permanent protection making future removal easier. Sacrificial coatings are removed along with graffiti, then reapplied. Permanent coatings allow graffiti removal without coating damage. Both types simplify future maintenance and reduce long-term costs.

For Dallas commercial properties, rapid graffiti removal and protective treatments maintain professional appearance and deter repeat vandalism.

- -Surface-appropriate removal techniques

- -Porous and non-porous surface expertise

- -Shadowing treatment and resolution

- -Sacrificial coating applications

- -Permanent anti-graffiti protection

Water Reclamation and Environmental Compliance

Professional exterior cleaning must address environmental regulations governing water discharge and chemical use. Responsible services implement practices that clean effectively while protecting the environment.

Water reclamation captures wash water preventing discharge into storm drains that lead directly to waterways. Vacuum recovery systems collect water for proper disposal or treatment. This is particularly important when cleaning petroleum stains, chemical residues, or areas where water contains significant contamination. Dallas and Texas regulations may require water recovery depending on the cleaning location and contaminants present.

Chemical selection considers environmental impact. Biodegradable cleaning agents break down after use, reducing aquatic toxicity. Phosphate-free formulations prevent water quality issues. Proper dilution and application minimize chemical usage while maintaining effectiveness.

Containment practices prevent cleaning solutions from reaching landscaping, water features, or storm drains. Berms, vacuum systems, and careful application control material flow. Waste water testing may be required before disposal to ensure regulatory compliance.

For Dallas businesses, environmentally responsible cleaning protects against regulatory violations while demonstrating corporate sustainability commitment.

- -Wash water recovery and containment

- -Environmentally responsible chemical selection

- -Biodegradable cleaning agents

- -Proper disposal compliance

- -Sustainable cleaning practices

Equipment and Surface Type Considerations

Professional pressure washing requires appropriate equipment selection and technique adjustment for each surface type. Understanding these variables ensures effective cleaning without damage.

Pressure equipment ranges from light-duty electric units (1,300-1,800 PSI) suitable for vehicles and delicate surfaces, to heavy-duty commercial machines (3,000-4,000+ PSI) for concrete and heavy stripping. Hot water capability (up to 250°F) improves cleaning effectiveness for grease, oil, and organic matter. Variable pressure and flow rate adjustment matches equipment to specific applications.

Surface considerations dictate approach: wood requires lower pressure to prevent fiber damage and raised grain; soft stone like limestone needs gentle cleaning to prevent etching; EIFS and synthetic stucco cannot tolerate high pressure; painted surfaces need pressure below paint removal threshold; and concrete accepts highest pressure but new concrete requires curing time before cleaning.

Nozzle selection affects cleaning pattern and intensity. Fan nozzles provide wide cleaning paths; rotary nozzles concentrate power for stubborn stains; surface cleaners provide uniform cleaning on flat areas. Professional operators understand equipment capabilities and limitations, selecting appropriate tools for each task.

For Dallas commercial properties, professional equipment and expertise prevent the damage that inexperienced operators cause with rental equipment.

- -Equipment selection by surface type

- -Hot and cold water capabilities

- -Variable pressure adjustment

- -Appropriate nozzle selection

- -Operator expertise and training

Frequently Asked Questions

What is the difference between pressure washing and power washing?

The terms are often used interchangeably, but technically refer to distinct processes. Pressure washing uses unheated water under high pressure for cleaning. Power washing (sometimes called hot water pressure washing) adds heat to the water, typically up to 250°F. Hot water significantly improves cleaning effectiveness for grease, oil, organic matter, and some stains by breaking down substances that cold water cannot dissolve. Power washing is preferred for: automotive and grease stains; gum removal; sanitization applications; and heavy industrial cleaning. Pressure washing suffices for general dirt, dust, and loose material removal. Cold water washing uses less fuel and may be preferred for environmental or cost reasons when heat isn't necessary. Professional services select the appropriate method based on surface type, contamination, and cleaning objectives. Both methods require proper technique to avoid surface damage.

Is pressure washing safe for all building materials?

No, pressure washing is not appropriate for all materials, and improper use damages surfaces. Materials generally safe for pressure washing include: concrete and masonry; brick (with appropriate pressure and technique); some metal surfaces; and certain types of stone. Materials requiring caution or soft washing include: vinyl siding (high pressure forces water behind panels); wood (excessive pressure splinters and raises grain); stucco and EIFS (pressure damages finish coat); asphalt shingles (pressure removes granules and causes leaks); painted surfaces (pressure strips paint); and windows and glass (pressure breaks seals and forces water infiltration). Professional assessment determines appropriate methods for each surface. Soft washing—low pressure with cleaning solutions—safely cleans delicate surfaces that pressure washing would damage. Experienced technicians know the pressure thresholds, nozzle distances, and techniques that clean without harm.

How often should commercial exteriors be pressure washed?

Pressure washing frequency depends on building location, surrounding environment, surface types, and appearance standards. General guidelines include: building facades—annually to bi-annually depending on soiling rate; concrete surfaces including sidewalks and parking areas—quarterly to semi-annually; high-traffic loading docks—monthly to quarterly; parking garages—semi-annually to annually; and graffiti removal—as needed immediately upon occurrence. Dallas environmental factors affect frequency: dust and pollen accumulation during dry seasons; humidity promoting biological growth; intense UV accelerating surface oxidation; and proximity to highways or industrial areas increasing airborne soil. Facilities pursuing consistent professional appearance may schedule regular maintenance cleaning. Others clean when visible soiling appears. Professional assessment recommends appropriate schedules based on your specific facility conditions and appearance objectives.

Do you use environmentally friendly cleaning solutions?

Yes, professional pressure washing services offer environmentally responsible cleaning solutions that effectively clean while minimizing environmental impact. Options include: biodegradable surfactants that break down after use without aquatic toxicity; phosphate-free formulations preventing water quality degradation; plant-based degreasers for petroleum stain removal; and low-VOC (volatile organic compound) products reducing air quality impact. For situations requiring more aggressive chemistry—heavy oil stains, industrial contamination, or difficult biological growth—professional services select the most environmentally compatible effective option and implement containment practices preventing environmental release. Water recovery systems capture wash water for proper disposal rather than storm drain discharge. When feasible, hot water pressure washing reduces or eliminates chemical needs by using heat for cleaning action. Dallas facilities with specific environmental policies or LEED certification requirements can discuss green cleaning options to align exterior maintenance with sustainability goals.

Can pressure washing remove oil stains from concrete?

Pressure washing can effectively remove or significantly improve oil stains from concrete, though complete removal depends on stain age, oil type, concrete porosity, and previous treatment attempts. Fresh oil stains (less than 24 hours) remove most easily before deep penetration. Professional removal approaches include: application of degreasing agents that break down petroleum products; hot water pressure washing (200-250°F) that melts and emulsifies oils; surface scrubbing with stiff brushes working cleaning agents into concrete pores; and multiple treatment passes for heavy staining. Old, set-in stains that have penetrated deeply into concrete may not completely disappear, though professional treatment typically achieves significant improvement. Some residual shadowing may remain on porous concrete. After cleaning, concrete sealers prevent future oil penetration, making subsequent stain removal easier. For Dallas commercial parking areas and loading docks, regular professional cleaning and sealing maintains appearance while preventing permanent staining.

Service Areas

We proudly serve businesses throughout the Dallas-Fort Worth metroplex, including: